Go beyond Viscosity with

AMETEK BROOKFIELD VISCOMETERS!

Brookfield Viscometers has a reputation as the global leader in viscosity measurements for over 80 years because of their accuracy, reliability, and versatility. Brookfield viscometers are instruments used to measure the viscosity of fluids. Viscosity is a measure of a fluid’s resistance to flow, and it is an important property for quality control, research and development, and process optimization in various industries, such as food, pharmaceuticals, beverage, lubricant, paints, and petroleum where the flow properties of liquids are critical to product performance and consistency. Brookfield viscometers are designed for measuring non-flowing materials like putty, gels, pastes, and creams.

The basic principle of a Brookfield viscometer involves measuring the torque required to rotate a spindle or rotor immersed in a fluid at a constant speed. The viscosity of the fluid is then calculated based on the measured torque. The resulting viscosity value can be displayed in different units, such as centipoise (cP) or millipascal-seconds (mPa·s), depending on the specific model and configuration of the brookfield viscometer.

Accurately measure the viscosity of fluids with our various Brookfield Viscometers.

DVPlus Viscometer

- Our newest model is suitable for all applications where accurate viscosity and yield stress measurements are needed

- The easy-to-use, stand-alone interface makes DVPlus the perfect Viscometer for busy labs

- With the DVPlus Viscometer, you get it all: high accuracy, fast response time, and repeatable results.

- Easy-to-use,stand-alone instrument for measuring viscosity and yield stress.

- Available in a Standard version and a 21 CFR Part 11 Compliant version.

DVNext Cone/Plate Rheometer

- Determine absolute viscosity of small samples (0.5 – 2.0 mL)

- Quick Set up with New Viscosity Wizard and Digital Leveling

- Ethernet and LIMS Connectivity

- Updated Gap Settings

- Compliant to 21 CFR Part 11 in Stand-alone Mode

DV2T Touch Screen Viscometer

DV2T Touch Screen Viscometer

- 5-inch full color, touch screen display supports multiple languages

- Enhanced Security provides enhanced security with customizable user levels & password access to comply with regulatory requirements such as 21 CFR Part 11.

DVE Low Cost Digital Viscometer

DVE Low Cost Digital Viscometer

- Low cost and easy to use

- 18 speeds for greater range capability (0.3 to 100 rpm)

Dial Reading Viscometer

Dial Reading Viscometer

- Continuous torque sensing capability

- Torque measurement accuracy: 1% of full scale range

- Repeatability: 0.2% of full scale range

CAP2000 Viscometer

CAP2000 Viscometer

- The CAP2000+ also offers lower shear rates, making it suitable for many applications where small sample volume and good temperature control are necessary

- Brookfield’s CAP-2000+ offers expanded temperature and viscosity ranges with variable speed capability

- The CAP2000+ also offers lower shear rates, making it suitable for many application where small sample volume and good temperature control are necessary

RSO Rheometer

RSO Rheometer

- Quick Connect Coupling System for easy spindle attachment.

- Instrument flexibility allows for cone/plate and concentric cylinder in one.

RSX Cone Plate Rheometer

RSX Cone Plate Rheometer

- RSX Cone Plate Rheometer is an advanced rheometer instrument for controlled rate and controlled stress measurements

- The RSX Cone Plate Rheometer operates both in controlled shear rate (rpm) and controlled shear stress (torque) modes—for sophisticated rheological analysis

RSX Coaxial Cylinder Rheometer

RSX Coaxial Cylinder Rheometer

- The RSX Coaxial Cylinder Rheometer is AMETEK Brookfield’s latest, full-featured rheometer, offering superior viscosity profiling, thixotropic response, yield stress determination and creep analysis

- A wide range of shear rate, shear stress, and torque provide flexible flow analysis including creep and yield measurement

- The RSX-CC Rheometer is designed to accommodate the high throughput required of quality control laboratories providing cost-effective, worry-free operation for a variety of laboratory applications

RSX SST Rheometer

RSX SST Rheometer

- RSX Soft Solids Tester Rheometer is an advanced rheometer instrument that uses vane spindle geometry in both controlled rate and controlled stress modes

- High-end, touch screen rheometer that operates in both controlled shear rate (rpm) and controlled shear stress (torque) modes to characterize creep behavior, yield stress, and viscosity profiles for pastes, slurries, and materials with particulates

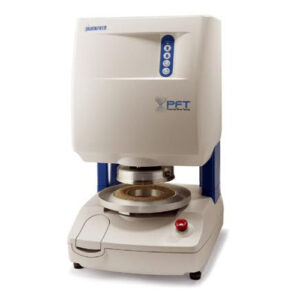

CTX Texture Analyzer

CTX Texture Analyzer

- Advanced model for compression and tension testing of materials.

- The addition of TexturePro Software makes the CTX ideal for R&D labs performing material evaluation/characterization tests.

CT3 TEXTURE ANALYZER

CT3 TEXTURE ANALYZER

- Choice of five load ranges up to 50kg

- A variety of probes and accessories for new application opportunities

- Choice of two adjustable base tables allows for versatility of sample testing

There are several models of Brookfield viscometers available, each with different features and capabilities. The LV, RV, HA, and HB models of Brookfield viscometers are available in different measurement ranges, allowing to cover a very wide range of viscosity, powder, texture, and process testing applications. The flexibility, use, dependability, and quality of service of Brookfield viscometers are relied upon by research labs, quality control, and production segments.

The AMETEK Brookfield viscometers and rheometers make it simple and quick to test viscosity and viscoelastic properties in a various applications. You can check the accuracy of your Brookfield viscometer using viscosity standards. Brookfield viscometers work by applying a controlled amount of shear stress to a sample of fluid and measuring the resulting shear rate. The relationship between shear stress and shear rate is used to calculate the viscosity of the fluid. These instruments are widely used because they provide accurate and reproducible measurements of viscosity, helping industries ensure the quality and consistency of their products.

The simple-to-use texture analyzers from AMETEK Brookfield measure the compression and tension of materials in a wide range of applications. For a wide range of industries and applications, Powder Flow Testers provide a quick and simple investigation of powder flow behavior.

Why Brookfield?

A variety of viscosity, powder, texture, and process testing applications are offered by Brookfield. Brookfield has a variety of Beverages, Food, Lubricants, Paint, Pharma, and other viscosity applications using different Viscometers and Rheometers.

Go beyond Viscosity with AMETEK BROOKFIELD!

Research labs, QC, Production segments rely on Brookfield instruments for Flexibility, Ease of use, Reliable performance, and quality of service.

AMETEK Brookfield’s rheometers allow for quick and easy viscosity and viscoelastic measurements in a wide range of applications. AMETEK Brookfield’s easy-to-use texture analyzers measure compression and tension of materials in a wide variety of industries. Powder Flow Testers deliver a quick and easy analysis of powder flow behavior for a wide variety of industries and applications.